US-based electrolyser company Plug Power has extended its reach into Australia’s fledgling renewable hydrogen market with a contract to collaborate on the engineering and design of a green ammonia production facility proposed for the Northern Territory.

Plug Power said on Thursday it has signed a Basic Engineering and Design Package (BEDP) with Allied Green Ammonia (AGA), an Australian company set up to build a large-scale, renewables-based hydrogen and ammonia production project in Gove in the NT.

The BEDP contract follows a memorandum of understanding for the supply of 3GW of Plug’s Proton Exchange Membrane (PEM) electrolysers for the AGA project, with delivery slated to begin in the first quarter of 2027.

The new contract commits Plug Power to support AGA on the Front-End Engineering Design (FEED) for the hydrogen-to-ammonia facility and to incorporate its electrolysers into the plant’s basic design, paving the way for a final investment decision (FID) by the final quarter of 2025.

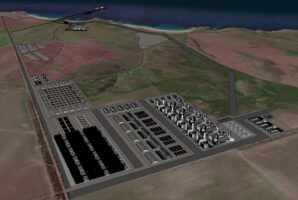

AGA’s Gove Peninsula project aims to generate 165,000 tonnes of renewable hydrogen a year to produce 912,000 tonnes a year of green ammonia – or 2,700 metric tons per day. It is targeting commercial operations to begin in the first quarter of 2029.

So far, the company has signed an interim land agreement with local landowners, the Gumatj Corporation, a process licence with Haldor Topsoe for use of its ammonia production technology, and a project development agreement with Tencuis Reunidos of Spain.

According to the CSIRO’s HyResource site, the project would benefit from the pre-existing port infrastructure and desalination plant, the latter of which would meet the project’s projected needs of around 1,750 ML/year of ultrapure water for hydrogen production through electrolysis.

“Our contract with Plug builds on a long list of leading global firms who are joining us on our journey to build one of the largest green ammonia production facilities in the world, in a strategically located part of Australia given its proximity to Asia,” said AGA founder and managing director Alfred Benedict.

“This BEDP agreement is a significant milestone in the development of Allied Green’s facility, which will be one of the most efficient green hydrogen and green ammonia projects globally.

“Given our respective track records in delivering clean energy infrastructure, this agreement is a critical first step and a testament to the alignment of our respective visions to provide tangible solutions that enable the world to achieve net-zero.”

Plug’s factory-assembled, modular PEM electrolysers offer a lower carbon alternative to Steam Methane Reforming (SMR) techniques and decrease downstream compression requirements using their pressurised 40 bar technology.

The company says the extracted oxygen from electrolysis-based hydrogen can also enhance efficiency in industrial power plants and furnaces due to its high-temperature combustion capability.

Plug CEO Andy Marsh said this week that moving the AGA project to the BEDP phase was a sign of its maturity in the development process, and another feather in the cap for Plug.

“In total, we now have 7.5 GW of BEDP contracts globally to support our growth targets,” he said.

The Nasdaq-listed last year signed on as the preferred supplier of the 550MW of hydrogen electrolyses Fortescue will need for its Gibson Island green hydrogen and ammonia project in Queensland.

Plug and Fortescue have also signed an MoU that includes potential collaboration on a number of large green hydrogen projects overseas, including equity swaps in Fortescue’s proposed Pheonix hydrogen plant and in Plug Power’s Texas hydrogen plant.

Elsewhere in Australia, Plug has committed to supply two 5MW electrolysers to Tasmanian hydrogen hopeful Countrywide Hydrogen, to be installed in Brighton, near Hobart, and Western Junction near Launceston.

And in the US, the federal Department of Energy this week awarded Plug Power a $US1.66 billion conditional loan to finance the development and construction of up to six green hydrogen production facilities in that market.